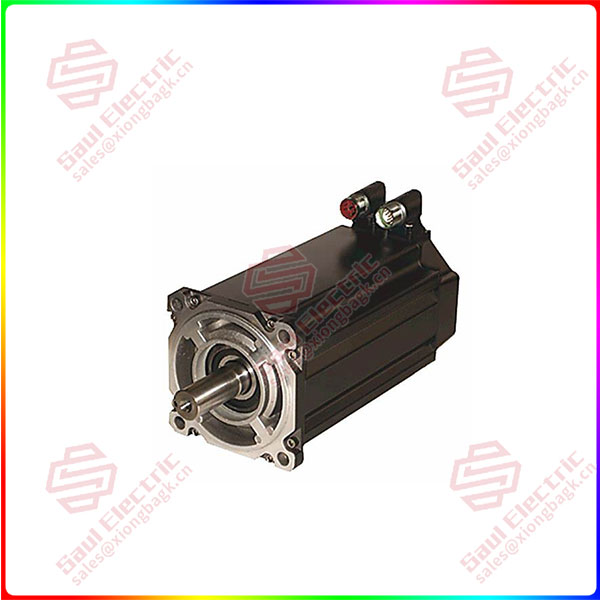

The MPL-B980E-MJ72AA servo motor can be used in typical applications such as automotive, metal forming, packaging, converting, material forming, and electronics assembly applications. The MPL-B980E-MJ72AA servo motor has a rated speed of 2500 revolutions per minute and it has the standard factory designated control options. For the proper functioning of the motor, the electromagnetic compatibility level should be improved by observing the correct cable routing procedure and careful cable construction. When installing the cables, the cable lengths should be kept to the required minimum length and cables carrying sensitive signals such serial, I/O, and encoder signals should be routed away from the input power wiring and the motor power wiring. To prevent electromagnetic interference, the encoder cable shield should be grounded at both ends. Additionally, the signal wire pairs should be twisted to reduce EMI interference.

1 Year Warranty

1 Year Warranty