Description

Overview

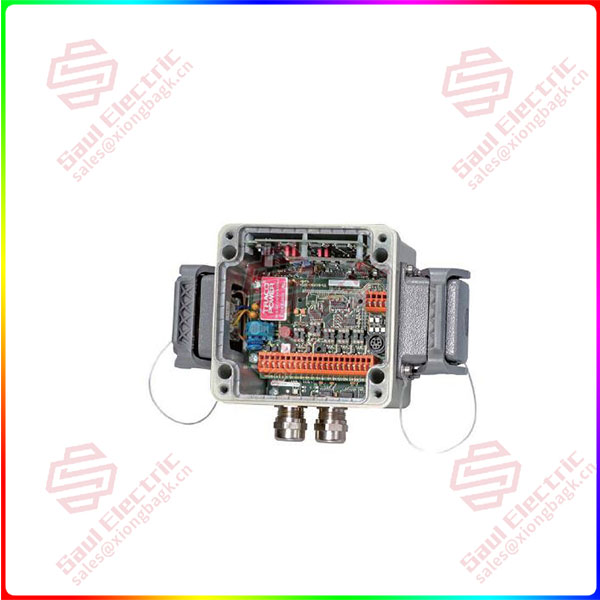

Essential details:MMS3110/020-020 Shaft-Vibration Monitor

Emerson’s Dual-Channel Shaft-Vibration Monitor is designed for small and low channel applications such as small steam, gas, and hydro turbines, and such as compressors, pumps, and fans to measure relative shaft vibration signals. Measurement settings, alarms, and provided outputs are field configurable via software.

Applications:

The two-channel axial displacement transmitter MMS3210 is part of the MMS3000 transmitter family and is used to monitor axial displacement, shaft position, thermal expansion and radial displacement, thrust bearing and valve position and many other applications using eddy current displacement sensors. It is also suitable for combined measurements of two sensors, such as maximum values in accordance with API670 or cone measurements and compensation measurements.

The input of the transmitter is the epro eddy current displacement sensor PR6422/… , PR6423/… , PR6424/… , PR6425/… , and PR6426/… .

MMS3125/022-020

Superiority products MMS3110/020-020 Shaft-Vibration Monitor

Applications include various types of turbomachinery, large and small steam turbines, fans, blowers, compressors, gear boxes, centrifuges, pumps, coal mills and others.

This system is not only suitable for large equipment in power plants, refineries and chemical plants, combined with fieldbus and PLC, main computer and network, but also suitable for independent monitoring of small turbomachinery with few measuring points.

This transmitter is not explosion-proof.

Function and principle:

The MMS3210 dual channel axial displacement transmitter converts two independent eddy current displacement sensor inputs into two independent outputs proportional to displacement.

A built-in “self-check” circuit monitors sensor and transmitter circuit faults, and if a fault is found, the logic “OK” output changes state while the current output changes from 4-20mA to 0mA. Initial setup is done by toggle switches and knob switches. The factory setting of the transmitter is the most commonly used working mode, and the factory can also be set according to user requirements.

1 Year Warranty

1 Year Warranty