Description

The CP500 control panels are obsolete and were replaced by the CP600 and CP400 control panel series. More information is provided via the Control Panels link below.

The CP500 control panels fulfilled the requirements of automated processes for more transparency and efficiency: they provided detailed information about the conditions and activities of machines and installations and made manual interference possible. The CP500 assortment covered the range from a monochrome CP501 with two lines of text to a CP555 with 10.4” color TFT touch display. All devices supported serial communication to the AC31 PLCs.

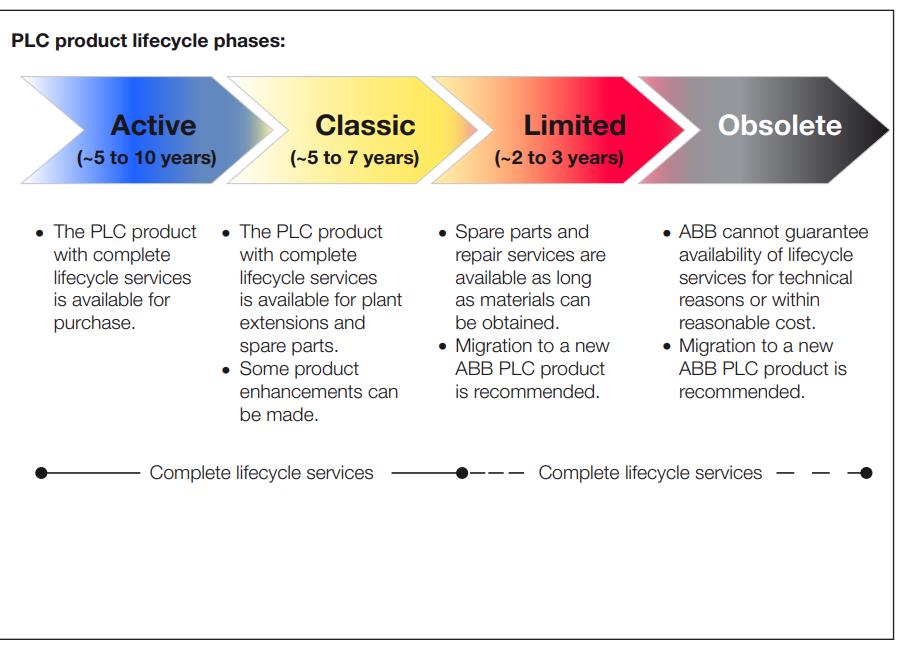

ABB has developed a product lifecycle management model aimed at providing service to maximize availability and performance

The CP500 control panels are obsolete and were replaced by the CP600 and CP400 control panel series. More information is provided via the Control Panels link below.

CP500 control panels with text display

- LCD with background illumination

- Memory: CP501: 16 kB; CP502, CP503: 64 kB

- CP502, CP503:

- Real time clock

- Recipe management

- Password protection, 8 levels

- Multi language support

CP500 control panels with graphics display

- LCD with background illumination

- CP513 with color display

- Graphics and text display

- Real time clock

- Trends

- Recipe management

- CK516 (keyboard) management

- Password protection, 8 levels

- Multi language support

- Memory: 400 kB

CP500 control panels with touch display

- LCD with background illumination

- CP554, CP555 with TFT color display

- Graphics and text display

- Real time clock

- Trends

- Recipe management

- CK516 (keyboard) management

- Password protection, 8 levels

- Multi language support

- Memory: CP551, CP552, CP554: 400 kB; CP555: 1600 kB

Lifecycle management model

The PLC lifecycle management model provides not only optimum support to end-users but also a smooth transition to a new PLC product when the service life of the current product ends.

The model divides a product’s lifecycle into four phases: active, classic, limited and obsolete. Each phase has different implications for the enduser in terms of services and support provided.

Benefits of lifecycle management

PLC lifecycle management maximizes the value of the equipment and maintenance investments by:

• ensuring spare parts and competence availability within the lifecycle

• enabling efficient product support & maintenance for improved reliability

• adding functionality to the initial product by following the upgrade path

• providing smooth transition to new technology at the end of the lifecycle

1 Year Warranty

1 Year Warranty