Description

Overview

Essential details:HT401-222-8/0 HT 401 and HT 402 are portable controls

The HT 401 and HT 402 are portable controls and display terminals for industrial applications. Due to its field bus compatibility, the large display and the optimized ergonomics, the handheld terminal is suitable for a great variety of tasks:

• Operator panel for machines and plants

• Teach panel for the testing mode of robots

• Setup device for drives

• Handheld device for machine tools

Compared to the HT 401, the HT 402 features a larger memory and graphic functions for the HT display.

The HT 40x (HT 401 / HT 402) is programmed using the programming software supplied with. The handheld terminal is available in the following versions:

Housing

• CE conforming housing

• Housing form conceived for both left- and right-handers

• Impact-resistant plastic housing withstands oil, grease, alcohol, and condensates containing hydrochloric acid, nonflammability (UL94-V0)

• Rubber bushing at cable entry for cables with a diameter from 8 to 11 mm Operating and display panel

• 40 membrane keys with tactile feedback, transparent key surface and rim embossing

• 40 2-color LEDs (red and green), 1 LED is assigned to each key

• 4 slots for individual key labeling

• Slot for individual device labeling (e.g. company logo) (except HT 401-8×20 and HT 402)

• Buzzer installed in the back of the device for keyclick and audible alarm

• LED-backlit supertwist LC display with 4 x 16 characters Operating safety

• The devices meet the standards EN60204-1 (Safety of machinery – Electrical equipment of machines) EN61131-1 and -2 (Programmable controllers)

• EMC standards

EN50081-2 (EMC – Generic Emission Standard) and

EN50082-2 (EMC – Generic Immunity Standard)

• Emergency stop switch in accordance with EN418 (Safety of machinery):

2 potential-free normally closed contacts for connecting external peripherals, nominal voltage 24 V (Safety low voltages in accordance with EN61131-2 and EN50178 (Electronic equipments for use in power installations)), maximum current 500 mA.

The emergency stop switch can also be evaluated by the software.

• Enabling switches in accordance with EN 60204-1 in safety categories in accordance with EN 954-1:1996 (safety-related parts of control systems):

2-channel, 3-position: safety category 3

2-channel, 2-position: safety category 3

1-channel, 2-position: safety category B

2 potential-free normally open contacts for connecting external peripherals, nominal voltage 24 V DC (safety low voltage in accordance with EN 61131-2 and EN 50178), maximum current 500 mA DC.

HT401-222-8/0

lf you need to inquire or purchase ,please send the product models to my email or call medirectly .

sunny He

[Email] sales@xiongbagk.cn

[Mobile] 86-18059884797

[WhatsApp] 86-18059884797

[Skype] sales@saulcontrol.com

HT401-222-8/0 HT 401 and HT 402 are portable controls

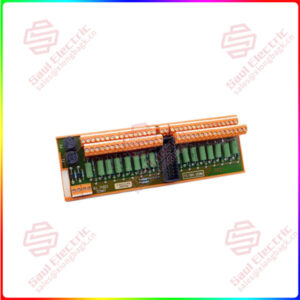

● Turbomachinery I/O Modules

Combined use of an FCN autonomous controller and turbomachinery I/O modules makes it possible to control and protect turbomachinery such as turbines and compressors. With the STARDOM turbomachinery controller, a flexible system can be constructed according to the scope of control and the installation space.

Of the turbomachinery control and protection functions, processing that requires high speed response is carried out by the turbomachinery I/O modules. There are two types of turbomachinery I/O modules: a servo module that performs high speed servo control in a cycle of 5 ms and a high speed protection module that performs a high speed protection action in a fast scan (5 ms) or a standard scan (10 ms).

FUNCTIONS

The primary functions of a turbomachinery controller comprise of regulatory control of the turbomachinery speed, load, and fluid pressure, and so on, and protection of the turbomachinery from anomalies. Control and monitoring of ancillary facilities can also be added if necessary.

● Configuration Types

There are two types of configuration for the STARDOM turbomachinery controller.

Type 1: Configuration with a short base module

Type 2: Configuration with a long base module

The following table shows a list of the functions of each configuration

1 Year Warranty

1 Year Warranty