Description

Overview

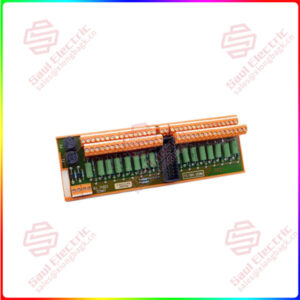

Essential details:VE4003S2B6 DeltaV™ M-series Traditional I/O

sunny He

[Email] sales@xiongbagk.cn

[Mobile] 86-18059884797

[WhatsApp] 86-18059884797

[Skype] sales@saulcontrol.com

VE4003S2B6 DeltaV™ M-series Traditional I/O

Product Description

/0 Card Redundancy

Redundant l/O cards are available for critical applications.The same card can be used in simplex or redundant

applications. When installed on a two-wide redundant terminalblock, the cards are recognized as a redundant pair by thecontroller. The controller scans each card and determines whichcard is acting as the active interface. When a fault is detected.the system automatically switches to the standby l/O card.

DeltaV Control modules reference simplex and redundant1/0 channels identically and there is no special confiquration

required to take advantage of redundancy.

Switchover of a redundant l/O card is completed within

two scans of the l/O bus. Make-before-break contacts ensure

digital field instruments remain powered and the processis undisturbed. Analog output signals are briefly driven byboth cards for < 5 ms during switchover of the card.

Events that can cause a switchover include.

Hardware failure within the active card.

mCommunications failure between the active cardand the controller.

m Detection of a fault in the field wiring.

A switchover may also be initiated from the diagnosticsexplorer, and the health and status of both cards andtheir channels are available in the diagnostics explorer.

The system automatically commissions a new standby card.In safe areas, failed cards can be replaced under power.In hazardous areas, appropriate installation proceduresmust be followed.

Hardware Alerts automatically report hardware integrity errorsfor both the primary and secondary cards. Any event that

causes a switchover is also reported automatically through thesystem hardware alerts and is logged in the Event Chronicle.

1 Year Warranty

1 Year Warranty