Description

Overview

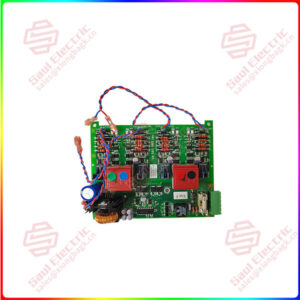

Essential details:SMC9915-501-000-1D-1 servo amplifier GLENTEK

The function of servo amplifier is to synthesize and amplify multiple input signals and feedback signals, and output corresponding signals to control the servo motor forward or reverse according to the polarity of the integrated signal. When the input signal and the feedback signal are balanced, the servo motor stops rotating, and the output shaft of the actuator is stable in a certain position.

The servo amplifier group is composed of a pre-magnetic amplifier, a trigger, a main circuit of thyristor and a power supply, as shown in the figure below. Servo amplifier block diagram

To meet the needs of complex multi-parameter regulation, the servo amplifier is set up by three input signal channels and one position feedback signal channel. Therefore, it can input three input signals and a position feedback signal simultaneously. In a simple regulation system with one parameter, only one input channel and one feedback channel are used.

In the servo amplifier, the pre-magnetic amplifier combines three input signals and one feedback signal into a deviation signal and amplifies it into a voltage signal U22-21 output. At the same time, the output voltage is converted into a trigger pulse by trigger 1(or 2) to control the thyristor turn-on of the main circuit 1(or 2) of the thyristor, so that the AC 220V power supply is added to the winding of the two-phase servo motor to drive the two-phase servo motor to rotate. When △1>0, U22-21>0, trigger 2 and main loop 2 work, and the two-phase servo motor is turning forward; When △1<0, trigger 1 and main loop 1 work, and the two-phase servo motor reverses; The circuit composition and parameters of the two sets of triggers and the two sets of thyristor main loop are exactly the same, so when the input signal and the position feedback current If are balanced, the output of the pre-magnetic amplifier U22-21≈0, there is no trigger pulse output of the two triggers, the thyristors in the main loop 1 and 2 are blocked, the power supply of the two-phase servo motor is disconnected, and the motor stops rotating.

It can be seen that the servo amplifier is equivalent to a three-position contactless relay, and has a great power amplification ability.

SMC9915-501-000-1D-1

lf you need to inquire or purchase ,please send the product models to my email or call medirectly .

sunny He

[Email] sales@xiongbagk.cn

[Mobile] 86-18059884797

[WhatsApp] 86-18059884797

[Skype] sales@saulcontrol.com

SMC9915-501-000-1D-1 servo amplifier GLENTEK

1 Year Warranty

1 Year Warranty