Description

Overview

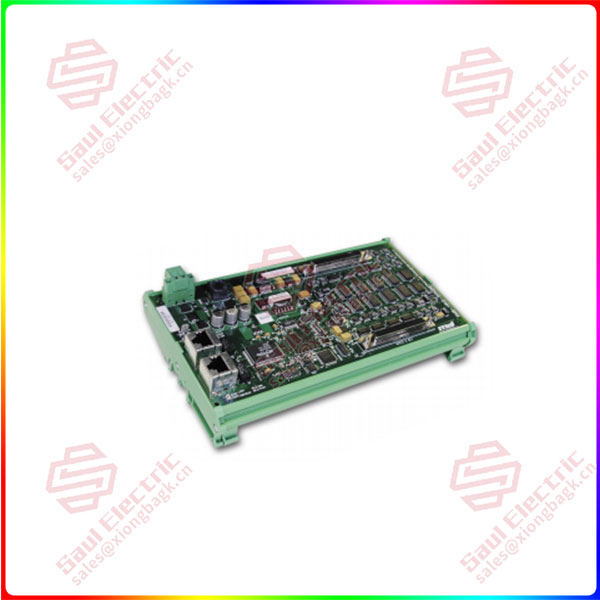

Essential details:RMB-10V2-SYNQNET Remote Motion Block

lf you need to inquire or purchase ,please send the product models to my email or call medirectly .

sunny He

[Email] sales@saulcontrol.com

[Mobile] 86-18059884797

[WhatsApp] 86-18059884797

[Skype] sales@saulcontrol.com

RMB-10V2-SYNQNET Remote Motion Block

The working principle of the servo driver is to receive the control signal from the upper controller and convert it into the corresponding motor control signal, so as to realize the precise control of the motor.

Specifically, the servo driver usually includes a position controller, a speed controller and a current controller. By receiving the position instruction sent by the upper controller, the position controller calculates the Angle and speed that the motor needs to rotate, and converts it into the corresponding current signal and sends it to the current controller. The current controller controls the current of the motor according to the received current signal, so as to achieve accurate control of the motor.

In practical applications, servo drivers are usually equipped with feedback devices such as encoders, which are used to monitor the position and speed of the motor in real time, and feed it back to the position controller, so as to achieve closed-loop control of the motor and improve control accuracy and stability.

In short, the working principle of the servo driver is to receive the control signal, convert it into the motor control signal, and control the current size of the motor through the current controller, so as to achieve accurate control of the motor.

1 Year Warranty

1 Year Warranty