Description

Overview

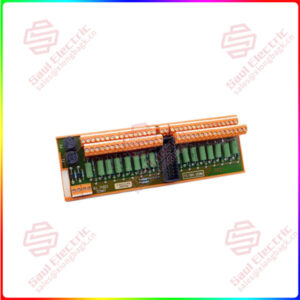

Essential details:RDCU-12C Manual RDCU Drive Control Units

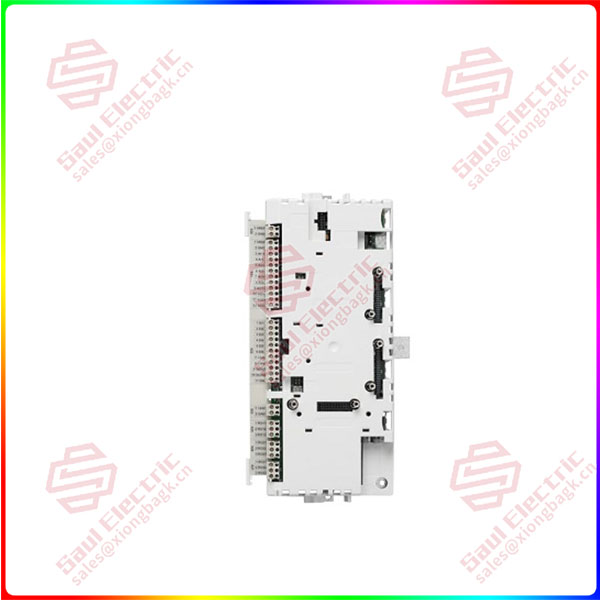

Designations A…C and J1 refer to the section Mechanical installation below. The connectors (X…) are explained under Technical data further below.

Setting J1 can be further facilitated by removing the cover (see Removal and

replacement of cover below for further instructions). The jumper can also be set using long-nosed pliers or tweezers without removing the cover.

• Align the four retaining clips (A) at the top and bottom edges of the cover with the mounting rail, and carefully press the module onto the rail until the clips catch on the edges of the rail.

• Using two screws, fasten the base plate of the RDCU by the two mounting holes (B) to the mounting rail. Make sure the contact surfaces are free from dirt or grease. This is essential for the operation of the control unit since the screws provide the grounding for the unit.

Removal of unit from mounting rail

• Remove the two screws (B) holding the base plate of the unit to the mounting rail. Carefully bend the retaining clips (A) at the upper and lower edges of the cover outwards to release the unit completely from the mounting rail.

Removal and replacement of cover

• Remove all detachable (screw-type) terminal plugs from the RDCU, and disconnect any cables connected to the unit. Remove any optional modules.

If desired, the unit can be removed from the mounting rail as described above to facilitate the following steps.

• With a screwdriver or similar tool, carefully release the four cover retaining clips (C) on the right-hand side while simultaneously pulling the right-hand edge of the cover gently away from the base plate.

• Shift the cover to the left to free its left-hand edge, then pull it to detach it completely from the base and circuit board.

• Replace the cover in reverse order to the above (left-hand edge first). If the unit is already mounted onto its mounting rail, align the retaining clips (A) so that they catch on the mounting rail.

RDCU-12C

lf you need to inquire or purchase ,please send the product models to my email or call medirectly .

sunny He

[Email] sales@xiongbagk.cn

[Mobile] 86-18059884797

[WhatsApp] 86-18059884797

[Skype] sales@saulcontrol.com

RDCU-12C Manual RDCU Drive Control Units

General

The shields of the I/O cables should be grounded to the chassis of the cubicle as close to the RDCU as possible.

Use grommets at all cable entries.

Handle fibre optic cables with care. When unplugging fibre optic cables, always grab the connector, not the cable itself. Do not touch the ends of the fibres with bare hands as the fibre is extremely sensitive to dirt.

The maximum long-term tensile load for the fibre optic cables included is 1 N; the minimum short-term bend radius is 25 mm (1”).

Digital/Analogue input/output connections

See the Firmware Manual of the application program in question. Installation of optional modules Follow the instructions given in the user manual of the module.

Other connections

See also the wiring diagram below.

Powering the RDCU

The RDCU is powered through connector X34. The unit can be powered from the power supply board of the inverter (or IGBT supply) module, provided that the maximum current of 1 A is not exceeded.

The RDCU can also be powered from an external 24 V DC supply. Note also that the current consumption of the RDCU is dependent on the optional modules attached. (For current consumption of optional modules, see their respective user manuals.)

Fibre optic connection to inverter/IGBT supply module Connect the PPCS link of the AINT (ACS 800 series modules) board of the inverter (or IGBT supply) module to fibre optic connectors V57 and V68 of the RDCU.

Note: The recommended maximum distances for the fibre optic link is 10 m (for plastic [POF] cable). In case longer distances are required, contact an ABB representative.

1 Year Warranty

1 Year Warranty