Description

概观

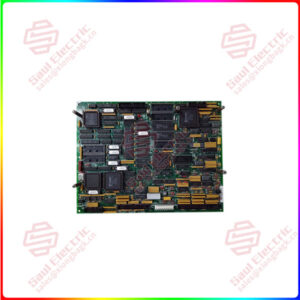

Essential details:MVI56-PDPMV1 ControlLogix Platform PROFIBUS DPV1 Master

lf you need to inquire or purchase ,please send the product models to my email or call medirectly .

sunny He

[Email] sales@saulcontrol.com

[Mobile] 86-18059884797

[WhatsApp] 86-18059884797

[Skype] sales@saulcontrol.com

MVI56-PDPMV1 ControlLogix Platform PROFIBUS DPV1 Master

There are two versions of the sample program: LEGACY (fixed I/O sizes) and FLEX (variable I/O sizes) versions.

MVI56-PDPMV1 firmware version 0.30 must use the LEGACY sample program and fixed I/O sizes.

MVI56-PDPMV1 firmware version 1.21 or later can use either the LEGACY or FLEX mode sample programs.

For module firmware version 1.21 or later, the USE LEGACY MODE configuration parameter in ProSoft Configuration Builder selects which mode you will use. Setting the parameter to YES uses fixed I/O sizes in LEGACY mode. Setting the parameter to NO uses variable I/O sizes in FLEX mode. This step is described in Selecting the Connection Parameters for the Module (page 69).

LEGACY mode allows backward compatibility with firmware version 0.30 and implements the following features:

Fixed backplane I/O block size (input = 250 words, output = 248 words)

Status and Mailbox transferred through regular I/O blocks. LEGACY mode offers these advantages:

Works with all module firmware versions; use LEGACY mode for backward compatibility in older applications.

Since all parameters are fixed, configuration is simpler than FLEX mode.

Status data is bought across the backplane as I/O data without the need for additional logic to trigger MSG instructions.

FLEX mode implements the following features:

Supports variable backplane I/O block sizes (input backplane block size can be set from 12 words to 250 words; output backplane block size can be set from 5 to 248 words).

Status, Slave Diagnostic, and Mailbox data transferred through MSG instructions.

Supports IOT instruction for immediate write of backplane output.

When transfer speed for smaller data configurations is a priority or when backward compatibility is not required, consider using FLEX mode, which provides these advantages:

Makes it easier to support installing the module in a remote rack. The flexible backplane I/O block size allows you to adjust the amount of data to transfer for any remote rack application and optimize network bandwidth utilization.

Improves backplane I/O block transfer performance by implementing MSG instructions to retrieve module status. This means regular I/O block transfers are not needed for status data, so process I/O data can be updated more often. The same applies to Mailbox MSG data transfers.

Improves backplane performance by implementing the IOT instruction for Immediate Output Transfers, which overrides the module RPI time and sends data as fast as possible.

1 Year Warranty

1 Year Warranty