Description

Overview

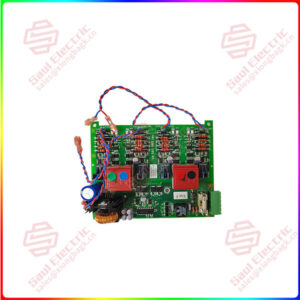

Essential details:ISH070/60017/011100/0100100100 SERVO MOTOR 70 MM

lf you need to inquire or purchase ,please send the product models to my email or call medirectly .

sunny He

[Email] sales@saulcontrol.com

[Mobile] 86-18059884797

[WhatsApp] 86-18059884797

[Skype] sales@saulcontrol.com

ISH070/60017/011100/0100100100 SERVO MOTOR 70 MM

The working principle of the servo motor can be simply summarized as follows: when the servo motor receives the control signal, the servo controller will process and analyze the signal, and then send the result to the servo motor. After receiving the signal, the servo motor converts the electrical signal into mechanical motion through the internal control algorithm and drive device, thus driving the control object.

The working principle of servo motor involves many important technical concepts and principles, including PID control, feedback control, motor drive and circuit design. PID control is a common control strategy that adjusts the control signal by comparing the difference between the actual output and the expected output to reduce errors and achieve precise control.

The servo system is composed of servo motor, servo controller and feedback device. The servo motor is responsible for generating the mechanical output force and torque, and the encoder is used to measure the position and speed of the motor and feed the measurement results to the servo controller. By constantly comparing the encoder’s measurements and control signals, the servo controller can adjust the output of the motor in real time to maintain the desired position and speed.

The working principle of the servo motor also involves pulse positioning. When the servo motor receives a pulse, it will rotate the Angle corresponding to one pulse to achieve displacement. The servo motor itself has the function of issuing pulses, so each rotation Angle of the servo motor will emit the corresponding number of pulses. The pulse received by the servo motor and the pulse emitted form an echo, and the system will know how many pulses are sent to the servo motor, and how many pulses are received back, so as to be able to accurately control the rotation of the motor and achieve accurate positioning.

To sum up, the working principle of the servo motor is to receive the control signal, which is processed and analyzed by the servo controller and converted into mechanical motion to drive the control object. By means of PID control, feedback control and pulse positioning, servo motor can achieve accurate position, speed and acceleration control.

1 Year Warranty

1 Year Warranty