Description

Overview

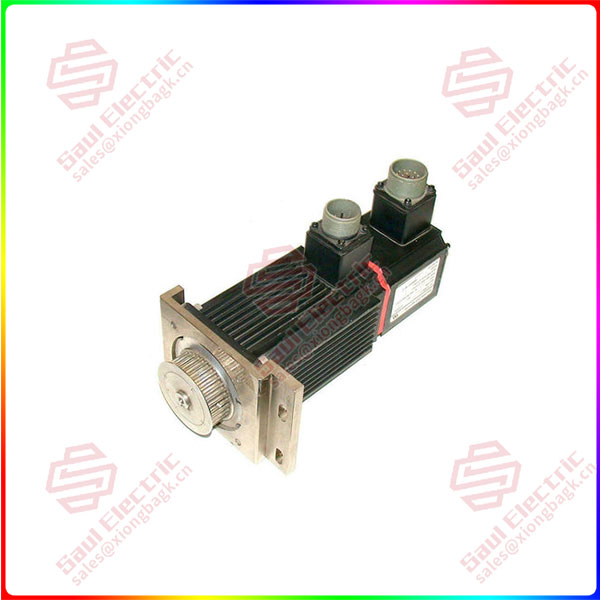

Essential details:H-3016-N-H00AA H-Series of AC servo motors

The H-3016-N-H00AA is an AC servo motor manufactured by Allen-Bradley. The Allen-Bradley H-3016-N-H00AA servo motor is part of the H-Series of AC servo motors. The Allen-Bradley H-3016-N-H00AA servo motor features 240 Volts AC voltage rating, a 5000 RPM speed rating, 1 Horsepower output, 6.8 Amps of current, 75 kW, 3-phase, 4.97 N-m torque rating, 2.5g peak at 30 to 2000 Hertz vibration rating, and 10.0g peak shock rating for 6 milliseconds duration. The Allen-Bradley H-3016-N-H00AA servo motor is housed in a NEMA 56C Enclosure. The Allen-Bradley H-3016-N-H00AA servo motor is equipped with an internal thermal switch that indicates overheating if it happens. The Allen-Bradley H-3016-N-H00AA servo motor’s watertight MS connections are compatible with the standard cable assemblies; also, the extruded aluminum framing and environmental connectors provide an IP65 package.

The Allen-Bradley H-3016-N-H00AA servo motor is economical, with a compact design capable of enduring harsh environments. The Allen-Bradley H-3016-N-H00AA servo motor is configured with optional spring-set holding brakes that are available with 24 Volts DC power. The Allen-Bradley H-3016-N-H00AA servo motor consists of an axially-trapped front bearing in a steel insert for long life at high speeds. The characteristics of the Allen-Bradley H-3016-N-H00AA servo motor also includes high acceleration and peak torques, high-speed point-to-point positioning, and an environmentally rugged design. The Allen-Bradley H-3016-N-H00AA servo motor can be combined with the ULTRA 100 1398-DM-019 drive, the ULTRA 200 1398-DM-020 drive, and both the ULTRA PLUS 1398-PDM-20 drive and the 1398-PDM-25 drive. The Allen-Bradley H-3016-N-H00AA servo motor operates in 0 to 40 degrees Celsius ambient temperature and at 5% to 95% non-condensing relative humidity.

H-3016-N-H00AA

lf you need to inquire or purchase ,please send the product models to my email or call medirectly .

sunny He

[Email] sales@xiongbagk.cn

[Mobile] 86-18059884797

[WhatsApp] 86-18059884797

[Skype] sales@saulcontrol.com

H-3016-N-H00AA H-Series of AC servo motors

1 Year Warranty

1 Year Warranty