Description

Overview

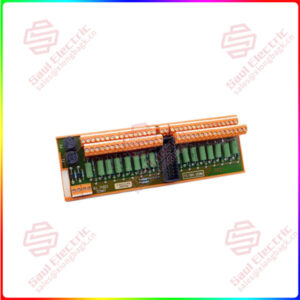

Essential details:FC-PSU-UNI2450U Safety Manager System Power Supply

lf you need to inquire or purchase ,please send the product models to my email or call medirectly .

sunny He

[Email] sales@saulcontrol.com

[Mobile] 86-18059884797

[WhatsApp] 86-18059884797

[Skype] sales@saulcontrol.com

FC-PSU-UNI2450U Safety Manager System Power Supply

Proper Maintenance when Safety is on the Line

Your Safety System is protecting your process equipment and mproper power supply maintenance ensures the system remains available. Each part of the system should be inspected and alarms acted upon immediately. The Safety Manager Systems

Troubleshooting and Maintenance Guide section 5 and the Fail Safe Controller FSC Service Manual section 7 provide further guidance and service checklists for actions to take to maintain the system properly providing longest life and best system performance.

The overall useful life of any electronic equipment can vary based on the environmental conditions they are exposed to where they are installed. The following are critical to the lifecycle of the PSU and continued health of the system.

Humidity

Humidity levels should be maintained between 40% and 60% with fluctuations of less than 6% rate-of-change per hour. If humidity is substantial, conditioned air along with humidity monitoring within the cabinet may be needed. During maintenance, look for traces of condensation anywhere in the cabinet – this is a signal that the climate control is beginning to fail.

Corrosion

Look at the paint and exposed metal surfaces within the cabinet for visible signs of corrosion. Corrosive salts and chemicals are kept out of the cabinet by keeping the door closed. Be aware of metallic debris such as airborne zinc that originates from the underside of raised floor tiles commonly used in computer rooms or any nearby hardware assembly or construction activities. If deterioration occurs that you can see, then even further damage is occurring in the components you cannot see and actions should be taken to further reduce contaminants

1 Year Warranty

1 Year Warranty