Description

Overview

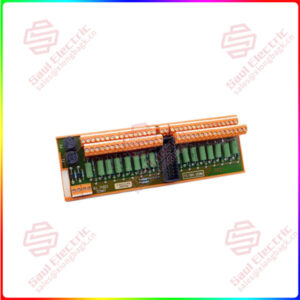

Essential details:AVR10D-Q22020 YOKOGAWA Control system ANB10D-420/CU2N/NDEL

Yokogawa Electric announced the development and release of OpreX™ Data Model Broker, a factory data transformation platform in the OpreX Smart Connection family of product lines. OpreX Data Model Broker can automatically verify the consistency of the plant design with the data scattered in the instrument system, and achieve data interoperability by applying ontology technology (an artificial intelligence technique *) to the operation and management of the database. Design Data Validation is a component released by Yokogawa for the platform that helps to systematically identify and validate inconsistencies between pipe and instrument drawings (P&ID) and 3D pipe drawings. This is a complex and time-consuming task. By automatically identifying such inconsistencies in large amounts of data, the component dramatically increases productivity and reduces the man-hours required for this type of work.

AVR10D-Q22020

lf you need to inquire or purchase ,please send the product models to my email or call medirectly .

sunny He

[Email] sales@xiongbagk.cn

[Mobile] 86-18059884797

[WhatsApp] 86-18059884797

[Skype] sales@saulcontrol.com

AVR10D-Q22020 YOKOGAWA Control system ANB10D-420/CU2N/NDEL

Development background

In recent years, with the increase in the size and complexity of the plant, the installation of equipment in the plant has become more and more complex. When a factory is built or expanded, the department responsible for each work area uses different design tools. The same goes for systems, where there are not only design and specification files, but also diagrams from equipment and equipment vendors, as well as engineering data from different system suites. Checking the consistency of data is usually done manually, which consumes a lot of manpower and man-hours. While 3D pipeline diagrams are typically only a few thousand, in a large project there may be 10,000 or more such files, all of which are currently checked manually. Therefore, there is an urgent need for a mechanism to use digital technologies to improve the interoperability of data and ensure its reliability.

To address this urgent need, Yokogawa has developed OpreX Data Model Broker, a factory data transformation platform that facilitates data interoperability and improves data utilization throughout the factory lifecycle.

peculiarity

Design Data validation in OpreX Data Model Broker automatically verifies the following conformance:

1. Pipeline attribute information

Double-check the pipeline property information in the P&ID and 3D pipeline diagrams.

2. Pipeline component attribute information and sequence

Verify the property information for each pipeline component and their sequence.

3. French specifications

If a pipe specification change is specified for the valve port in the P&ID, the pipe specifications for the relevant valves and flanges in the 3D pipe diagram are verified.

4. Flow direction of pipeline components

Check that the flow of each pipe assembly in the 3D pipe diagram matches the process flow in the P&ID.

* Ontology is a method of artificial intelligence technology. A concept or mechanism that defines the meaning of information so that computers mimic the way humans understand the meaning of information.

1 Year Warranty

1 Year Warranty