Description

Overview

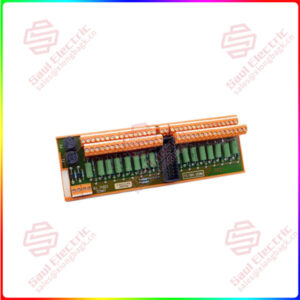

Essential details:AO2040/CALDOS Advance Optima process analyzer’s

The Advance Optima process analyzer’s modular design helps ensure the long-term security of your investment. The analyzer modules can be freely combined into tailor-made solutions and can be upgraded or expanded at any time to incorporate new capabilities. Easily connect and centrally operate remote modules.

Advance Optima provides you with the following benefits:

A central unit and various analyzer modules

– Supports universal control

– Supports the same connection technology

– Use a unified system shell

All analyzers use high-performance measurement technology and simplified calibration, eliminating the need for test gas cylinders.

– Photometer

– In situ laser analyzer

– Oxygen analyzer

– Trace oxygen analyzer

– Thermal conductivity analyzer

– FID Analyzer

Multi-analyzer system: There are up to four analyzer modules and up to six sample components in one system

Extensive automatic calibration via air calibration or an integrated calibration chamber without the need for standard cylinders

The self-check function indicates when maintenance is needed

Hazardous site approved models comply with ATEX and GOST-R, Classes 2G, 3G, and CSA Class I,Division 2

“Safety Concept” for the measurement of flammable gases in Zone 2, Class 3G

Provides Ethernet TCP/IP interfaces, OPC server, PROFIBUS, and Modbus interfaces

AO2040

lf you need to inquire or purchase ,please send the product models to my email or call medirectly .

sunny He

[Email] sales@xiongbagk.cn

[Mobile] 86-18059884797

[WhatsApp] 86-18059884797

[Skype] sales@saulcontrol.com

AO2040/CALDOS Advance Optima process analyzer’s

1 Year Warranty

1 Year Warranty