Description

Overview

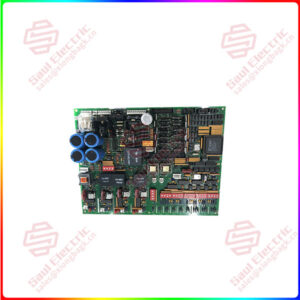

Essential details:9907-164 8200-1300 configurable steam turbine digital governor control

lf you need to inquire or purchase ,please send the product models to my email or call medirectly .

sunny He

[Email] sales@saulcontrol.com

[Mobile] 86-18059884797

[WhatsApp] 86-18059884797

[Skype] sales@saulcontrol.com

9907-164 8200-1300 configurable steam turbine digital governor control

The working principle of the digital governor of steam turbine is mainly based on the feedback control principle. It uses sensors to detect the actual speed of the turbine and converts the speed signal into an electrical signal. This electrical signal is then processed and compared with the set speed target value to produce an error signal. After the error signal is calculated and processed by the digital controller, a control signal is output to the turbine actuator, such as regulating the valve or fuel supply, to adjust the turbine speed.

Specifically, the working principle of the turbine digital governor can be divided into the following steps:

Sensor detection: The actual speed of the turbine is detected by a sensor (such as a speed sensor) installed on the turbine shaft. The sensor converts the speed into an electrical output.

Signal processing: The electrical signal output by the sensor is amplified, filtered and converted, so that the subsequent digital controller can accurately read and process the signal.

Controller calculation: The digital controller receives the processed speed signal and compares it with the set speed target value. According to the size and direction of the error signal, the controller calculates the control quantity that needs to be adjusted and outputs the corresponding control signal.

Actuator action: After the control signal is amplified, the actuator of the steam turbine is driven, such as regulating the valve or fuel supply. The actuator makes corresponding actions according to the size and direction of the control signal to adjust the speed of the turbine.

Feedback control: After the adjustment of the actuator, the speed of the turbine will change. This change is again detected by the sensor and fed back to the digital controller as a new speed signal. The controller continues to calculate and adjust according to the new speed signal to keep the turbine speed within the set target range.

Through this feedback control method, the turbine digital governor can realize the accurate control of the turbine speed, and adapt to the change of external load to ensure the stable operation and performance of the turbine.

1 Year Warranty

1 Year Warranty