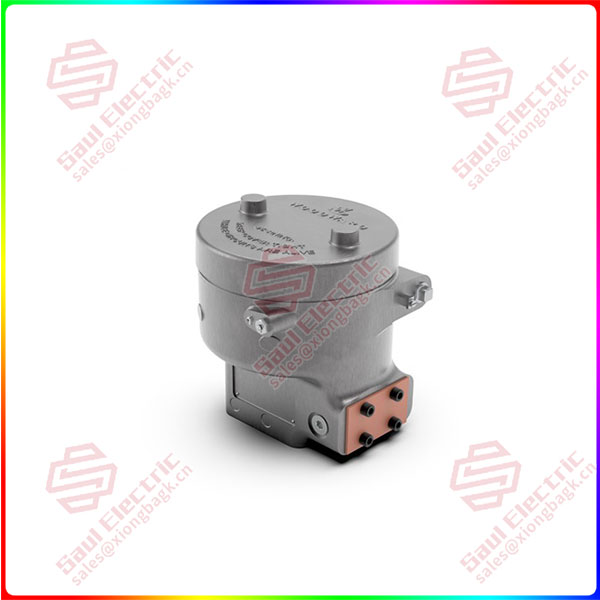

Woodward’s second generation current-pressure Converter (CPC-II) 10 bar, 2-zone, simplex version, with enhanced dynamics, is an electro-hydraulic pressure regulation control valve for positioning single-acting steam turbine valve servos/actuators. CPC-II addresses one of the industry’s number one reliability issues where oil contamination affects equipment uptime and performance.

The CPC-II accepts the 4-20 mA pressure demand signal and precisely controls the oil pressure to precisely position the single-acting turbine regulating valve. The accurate and stable control of steam valve is directly related to the improvement of turbine speed and load control, and the reduction of system mechanical wear.

Features:

Oil Pollution resistance (ISO20/16)

Precise fluid pressure control

Stable linear valve control

Includes valve linearization table (full range <0.2%)

Key application of redundant input/sensor

Receive signals from redundant controllers

Redundant (dual) CPC (master/slave) functions

Standard mounting and hydraulic connections

Self-cleaning valve algorithm

Status and health indicators (pressure sensor health, input demand signal health, internal device health, input power quality)

A software service tool for controlling pressure readings with trends

Comply with applicable CE directives ATEX, Machinery, PED and EMC

Replace:

Woodward CPC: 9907-1105, 9907-1106

1 Year Warranty

1 Year Warranty