Description

Overview

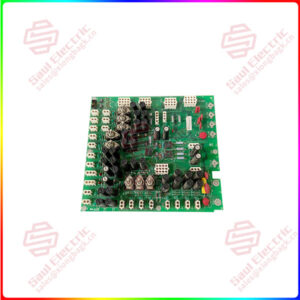

Essential details:8200-1301 rev. R Woodward Turbine Controllers

8200-1301 Technical Specifications

| Enclosure Type | IP20 when installed correctly |

| Features | Overvoltage 3 |

| Input Power (AC max) | < 73 W, 1.6 A max |

| Input Power (DC max) | < 73 W, 0.8 A max |

| Manufacturer | Woodward Turbine Controllers |

| Operating Temperature | –30 °C to +70 °C |

| Resolution | 800 x 600 pixels |

| Screen Size | 8.5 inches |

| Storage Temperature | –30 °C to +70 °C |

Product Description

The 8200-1301 is a Woodward 505 Digital Governor designed to be used with split range or single actuators. This is one of three versions available in this series, the other two being the 8200-1300 and the 8200-1302. The 8200-1301 is primarily used for AC/DC (88 to 264 V AC or 90 to 150 V DC) ordinary location compliance power. It is field programmable and uses menu-driven software for the control of mechanical drive applications and/or generators. This governor can be configured as part of a DCS (distributed control system) or it can be designed as a standalone unit.

The 8200-1301 has several different normal operating modes. This includes a configuration mode, a run mode, and a service mode. The configuration mode will force hardware into the I/O lock and put all outputs into a state of being inactive. Configuration mode is typically only used during the original configuration of equipment. Run mode allows for normal operations from start-up to shut down. Service mode allows for calibration and adjustments either when the unit is shut down or during normal operation.

The front panel of the 8200-1301 is designed to offer multiple levels of access to allow for tuning, operating, calibration, and configuration of the turbine. All turbine control functions can be performed from the front panel. It includes logic algorithms to control, stop, start, and protect the turbine using a number of input buttons.

For additional information regarding the 8200-1301, please refer to the original documentation from Woodward. Most of our in-stock products are available for shipment immediately.

8200-1300

lf you need to inquire or purchase ,please send the product models to my email or call medirectly .

sunny He

[Email] sales@xiongbagk.cn

[Mobile] 86-18059884797

[WhatsApp] 86-18059884797

[Skype] sales@saulcontrol.com

8200-1301 rev. R Woodward Turbine Controllers

Integrated Graphical Front Panel HMI Screen

- Multilingual screens including Chinese for easier operator use, diagnosis and control

- Large screen allows easy navigation and icon view of parameters and performance

- Real time trending locally viewable by operators and engineers

- Configurable tag names to easily identify connections

- Internal “Turbine Simulator” for off-line training and advance testing before system changes

Improved Communications

- Ethernet communications for connectivity to plant DCS, service tools and RemoteView operator control panels

- CANOpen actuator connectivity for Woodward VariStroke actuators and DSLC-II power management networks

Intelligent / Adaptive Control Algorithms

- Next generation advance load rejection performance

- 3 critical speed avoidance bands

- Reverse rotation sensing and alarm

- OptiTune adaptive PID technology for optimum set-up of turbine performance

- Acceleration PID that limits overshoots for a stable and efficient plant startup

- High speed data logs monitoring turbine operation and stress including run time and first out trip information

- Vibration monitoring for protection and control (Sensor kit 8928-7482)

Improved Service/User Tools

- Cyber compliant password enabled logins

- RemoteView (8928-5311) program enables virtual monitor and control from a remote workstation or mobile device

- Control Assistant service tool enabled to easily configure, save, compare and view settings and data logs

Drop-in upgrade for existing 505 legacy steam turbine governor controls with item number 9907-162 or 9907-163.

Use our convenient old 505 to new 505D retrofit wiring kit 5404-1801.

1 Year Warranty

1 Year Warranty