Description

Overview

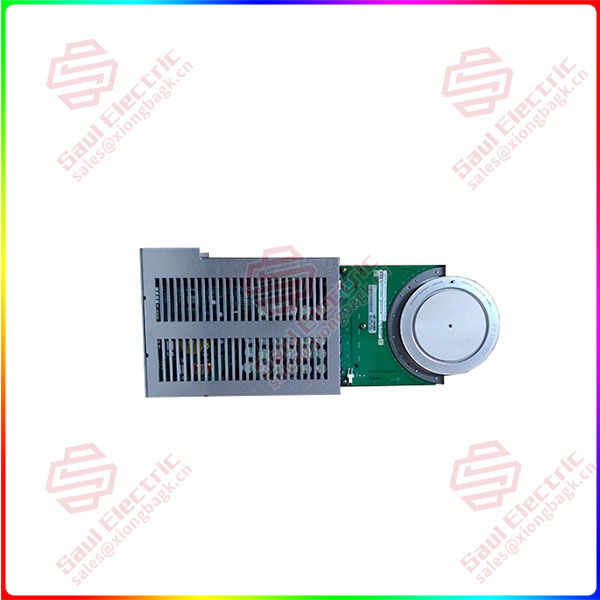

Essential details:5SGY3545L0003 Thyristor thyristor ABB

What are IGBT, IGCT and IEGT respectively, and what are the differences and commonalities?

Comparison of IGBT and integrated gate commutated thyristor IGCT

Limited by the current technical level, the working current of IGBT is relatively small, and the more commonly used medium and high voltage and high power IGBT has several specifications such as 1700V/ 2400A, 3300V/1200A, 4500V/ 900A, 6 500V/ 600 A, etc. The output capacity of the converter using the unit is generally not more than 1.6MVA, if you want to further increase the output capacity, you can only use the parallel connection of the components or the converter. Whether the components are used in series or parallel or the converter is used in parallel, it will increase the complexity of the system and lead to the reduction of efficiency and reliability.

5SHY3545L0020

Compared with GTO, IGCT has more obvious advantages: (1) there is no need to turn off the absorption circuit, which can reduce the volume and weight of the converter, improve the efficiency and reliability of the converter, and reduce the cost; Although the absorption circuit needs to be turned off when used in series, the volume is much smaller than that of GTO; (2) The gate drive circuit is integrated in the IGCT, and only the gate drive power supply interface and the optical fiber for transmitting the trigger signal and feedback state can improve the anti-electromagnetic interference capability of the converter; (3) Small on-state and off loss. The following figure shows the comparison of IGBT, GTO and IGCT at 3.3kV.

Figure 1: Comparison of IGBT with IGCT and GTO

As can be seen from the comparison of the above figure: IGCT loss is less. The switching loss of the three devices is not much different, and the switching loss of IGCT and IGBT is twice the difference, but the driving power of IGCT is much larger than that of IGBT. In short, IGBT in lower voltage applications, IGBT conduction loss is low, so cost-effective. IGCT is cost-effective at higher voltages. According to the use and design standards, there is an overlap between 1800V and 3300V.

Comparison of IGBT and electron injection enhanced gate transistor IEGT

IGBT is a MOS gate device, its gate is driven by voltage, high switching speed, so it has been widely used in the field of high frequency, but it also has some problems, such as low operating voltage, small capacity, high on-voltage drop and loss, which also limits its application. IEGT is a new device that has its advantages and overcomes its disadvantages. Commercial products have been developed in recent years. Compared with traditional devices. It has the advantages of low on-state voltage, small gate drive current, large power density, small switching loss and fast speed. FIG. 2 shows the comparison of IEGT and GTO gate parameters, and FIG. 3 shows the comparison of 4.5KV/3kA IEGT, GTO and IGCT performance for typical specifications

Author: Looking for ten times the bull stock

Link: https://xueqiu.com/8172031279/179543425

Source: Snowball

The copyright belongs to the author. For commercial reprinting, please contact the author for authorization. For non-commercial reprinting, please indicate the source.

Risk Warning: The views mentioned in this article are only personal opinions, the subject matter is not recommended, and trading accordingly is at your own risk.

lf you need to inquire or purchase ,please send the product models to my email or call medirectly .

Sales Manager: Manager He

E-mail number: sales@xiongbagk.cn

skype/ wechat: +86-18059884797

Mobile phone/wechat: +86-18059884797

QQ:3095989363

My company under the Sales and Marketing Department, technical engineering Department, after-sales service department, the department of comprehensive management. We can help your business with good service.

1. Sales Department 24/7 service. Handles your requests for any PLC DCS products in a timely manner with patience and professionalism.

2. The engineering department ensures that the products have no quality problems. All products will be inspected before shipping.

3. The financial department checks the payment and refund in time.

4. The warehouse department will carefully check the list of goods, carefully pack them, and deliver the goods in time.

5. After-sales Service Department has a full-time after-sales service team, subordinate to the sales department, and users can timely respond to service requests.

Shipping

1 Year Warranty

1 Year Warranty