Description

Overview

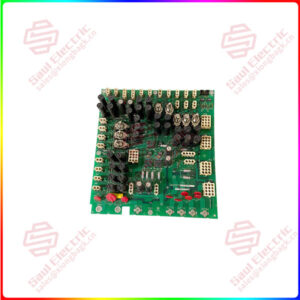

Essential details:5484-803 Plus 6 Actuator & Electronic Controller Systems

lf you need to inquire or purchase ,please send the product models to my email or call medirectly .

sunny He

[Email] sales@xiongbagk.cn

[Mobile] 86-18059884797

[WhatsApp] 86-18059884797

[Skype] sales@saulcontrol.com

5484-803 Plus 6 Actuator & Electronic Controller Systems

Four auxiliary control modules are available:

- Isochronous load sharing control

- Auto-synchronizer

- Ramp generator

- Single phase load pulse control

These and other auxiliary functions, such as remote speed setting and Kw limits, can be installed at the time of the initial governor installation or, just as easily, added later when the need arises. No modification to the basic governor is required when these auxiliary functions are added. In fact, if the prewired harness is used, the wires necessary to add these features are often already provided, further simplifying installation.

Speed Governing

APECS controllers are available for engine governing for speed and power control of piston and gas turbine engines where the fuel is controlled by the governor’s output shaft. The controllers are also applicable for controlling steam and water turbines.

Tandem Engine Governing

The APECS controller provides the precise positioning required for accurate tracking of two governor actuators used for controlling tandem-coupled engines.

No-Break Engine Governing

APECS controllers are designed to provide dual-mode operation. The controller functions with fixed gain when the engine is declutched and with an adjustable high gain when the engine is coupled to the load.

Propulsion Governing

APECS controllers are available for engine governing of propulsion engine applications. The controller has an adjustable low limit feature that is required to maintain correct engine operation due to the loading characteristics of the propeller. The same controller should be used on tandem-coupled propulsion engine applications.

Wide Speed Range Governing

APECS controllers provide governing for speed and power control of piston and gas turbine engines where the fuel is controlled by the governor’s output shaft.

The controller is designed to provide improved governor performance and control over a wider speed range than standard speed governors.

1 Year Warranty

1 Year Warranty