Description

Overview

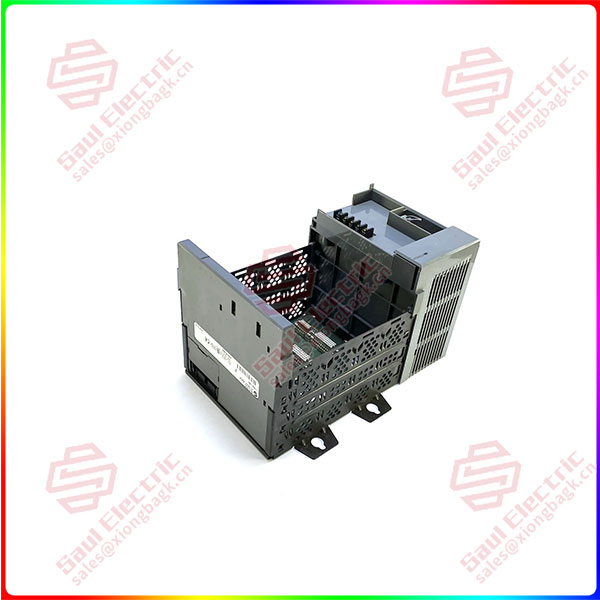

Essential details:1746-P2 SLC 500 Power Supply Allen Bradley

| Manufacturer | Rockwell Automation |

| Brand | Allen-Bradley |

| Part Number/Catalog No. | 1746-P2 |

| Series | SLC 500 |

| Module Type | Power Supply |

| Input Power | 70 Watts |

| Input Voltage | 120 to 220 Volts AC |

| Typical line power requirement | 180VA |

| Inrush Current | 20 Amps |

| Backplane Current (5 Volts) | 5 amps |

| Internal Current Capacity | 5 A at 5V dc; 0.96 A at 24V dc |

The Allen-Bradley 1746-P2 is an SLC 500 modular power supply. It comes with an input voltage of 85-132 or 170-265V AC at 47-63 Hz. Its internal current capacity at 5V is 5 A and it is 0.96 A at 24V. This power supply also comes with a maximum user-supplied overcurrent protection of 15 A and a maximum inrush current of 20 A. It has a 180 VA typical line power requirement and an input terminal and backplane isolation of 1800V AC RMS for 1 s. User-power current capacity at 24V DC is 200 mA and the user-power voltage range of the power supply, also at 24V DC, is 18-30V DC.

It has a maximum of two AWG wires per terminal. Fuse protection is present with the 1746-P2 power supply but it is limited to guarding against fire hazards due to short-circuit conditions. It comes with an open-type enclosure and can only be installed in a 1746 chassis. The entire power supply measures 5.5 x 2.9 x 5.7 inches and weighs 1.1 kg or 2.5 lbs. Its operating temperature is from 0-60 Deg. Celsius.

This power supply module has a jumper terminal that is used to set the input voltage to be applied to the device.

When undervoltage operation happens, the 1746-P2 power supply will continue to power up the SLC 500 controllers for a short period. When the power supply continues to receive input voltage that is lower than the recommended operating range for a period of time longer than the CPU hold-up time, the controllers will turn off. It will only resume operations automatically when the power supply receives the recommended operating input voltage.

For overcurrent conditions, the 1746-P2 Series A and B will undergo a power supply shutdown and CPU fault. The recovery procedure is to reload the user program. For the 1746-P2 Series C, it will have a 24V DC user shutdown but the CPU continues its operation and the recovery procedure is to correct the overcurrent condition.

The 1746-P2 is a Power supply module primarily designed for use with the SLC 500 automation system platform. This power supply is installed in the leftmost of the SLC chassis.

1746-P2

Superiority products 1746-P2 SLC 500 Power Supply Allen Bradley

1 Year Warranty

1 Year Warranty