Description

Overview

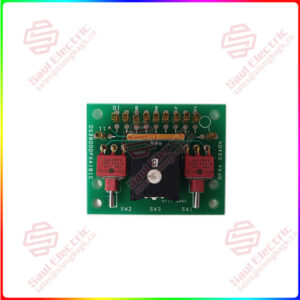

Essential details:Precharge PCB

Superiority products 1336-PB-SP2B Precharge PCB Allen Bradley

- The Allen-Bradley 1336-PB-SP23B board should be protected against harsh weather conditions because it can be damaged by moist environments. This PCB is not waterproof and it should be used for indoor applications only. The variable frequency drive that the PCB is attached to should be properly earthed during the installation process because the PCB is installed beneath the main control board of the drive. No traces of electromagnetic noise should be present near the installation area. The 1336-PB-SP23B board meets all the specifications that are required to meet different industrial standards. A grounding system should be used to minimize the electrical interference to the board. A specified temperature range between 0 and 50 degrees Celsius should be maintained in the installation environment for proper operation.

1 Year Warranty

1 Year Warranty